Bending

Our tube bending expertise, in conjunction with our capability to design and machine necessary tooling, allows us to fabricate complex compound angles on high-purity gas lines. With our computer numerical control (CNC) bender and ability to build fixtures for part compliance verification, we can ensure accurate and cost-effective results for high-production runs.

Gas Distribution Assemblies

Our line of custom-made, build-to-print assemblies enables more controlled, precise engineering for gas lines, valves, and manifolds. These assemblies are configurable to accommodate virtually any box size.

Particle Surface Testing

Particles can create defects on semiconductor surfaces, compromising quality and performance. Our particle detector offers precise measurement capabilities, detecting particles as small as 0.1 µm (within the 0.1 – 0.5 µm range), ensuring even the smallest contaminants are identified for removal.

Vertical Integration of Machined Blocks/Flanges

Our capability to hold precise tolerance and finishes allows us to produce the machined components used in gas delivery systems, which are essential for gas flow and contamination control throughout semiconductor manufacturing, including processes like deposition, etching, and doping. We offer a broad range of supporting products for optimized gas delivery, including UHP custom precision machined blocks and flanges.

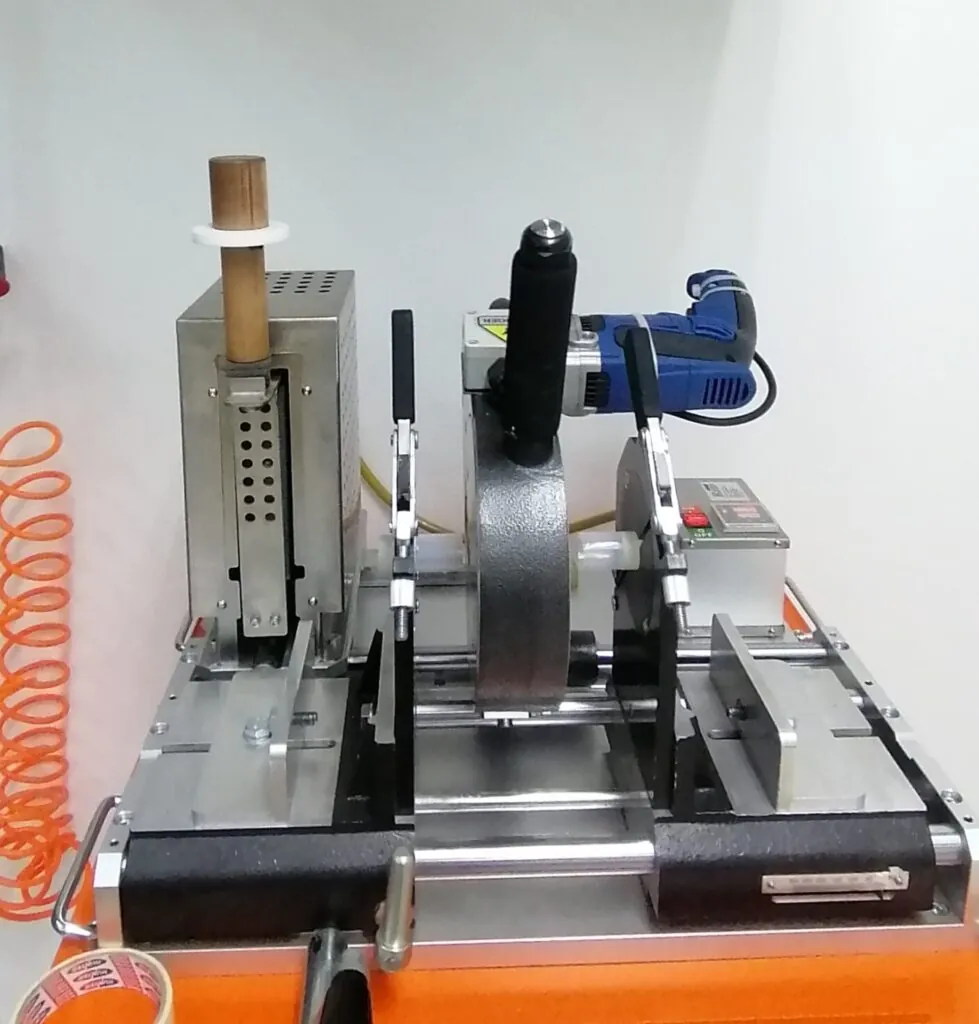

TIG Large Outside Diameter (LOD) Weldments

With our seven gas tungsten arc welding (GTAW)/TIG stations, supported by our machine shop for weld fixtures, we can provide solutions for complex LOD weldment fabrication and accommodate customer requirements efficiently for quick turnaround.

Ultrasonic Cleaning

Our UHP weldments are cleaned prior to welding through our in-house ultrasonic deionized (DI) water wash, which uses high-purity ultrasonic waves to remove contaminants, followed by a filtered nitrogen (N2) drying process. This meets the UHP orbital welded gas line requirements set by SEMI Standard E49.7.